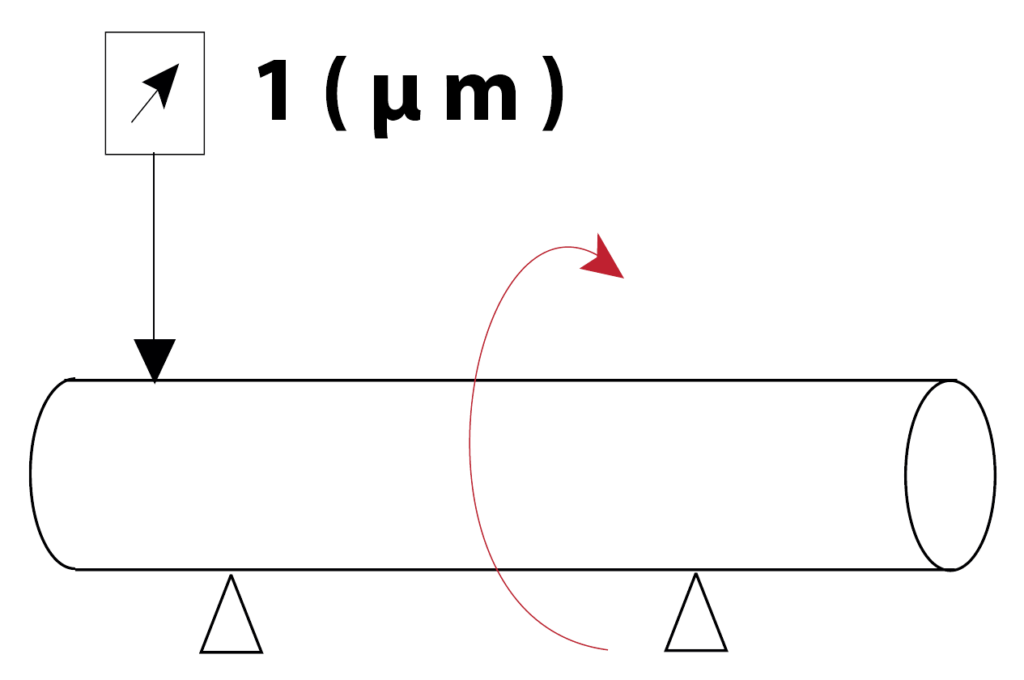

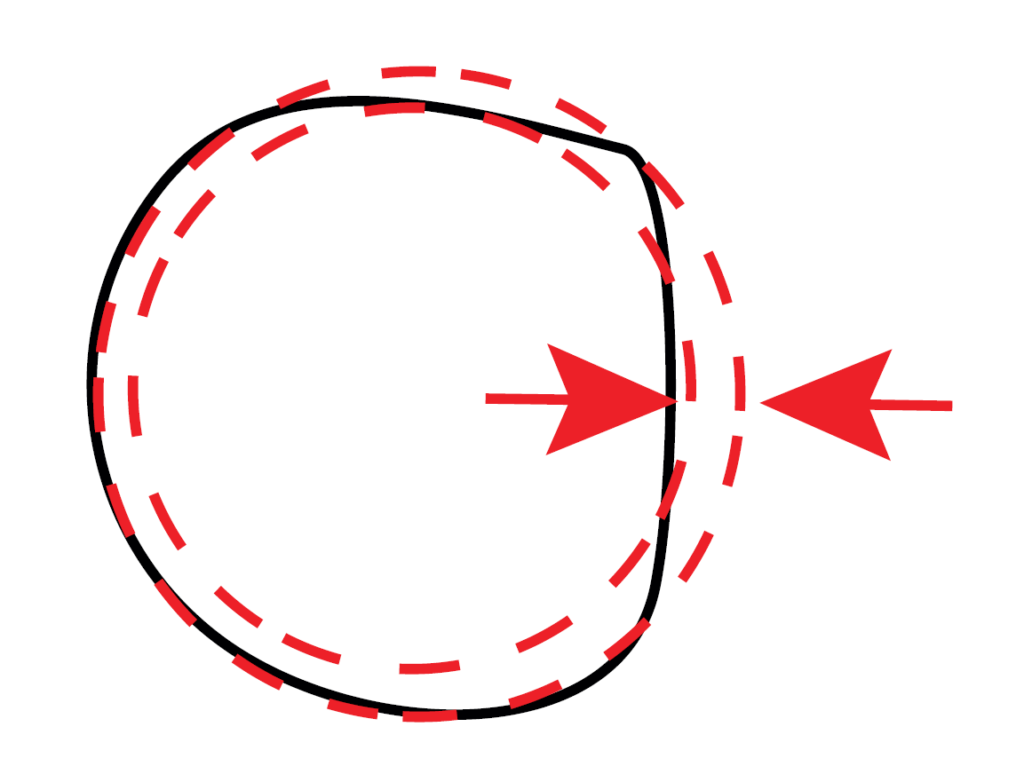

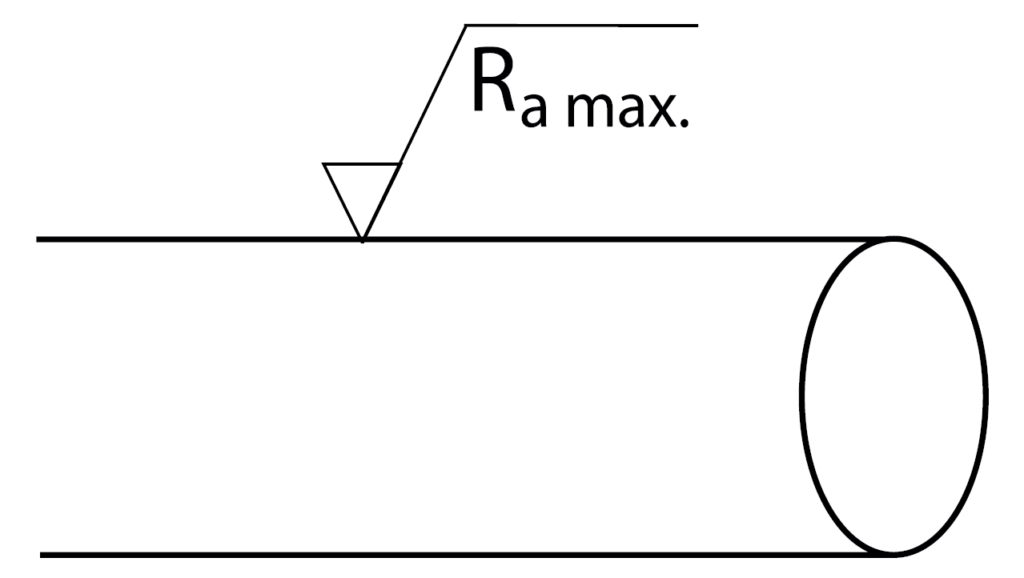

Super Carbide offers carbide rods made from different kinds of materials in sizes from 02 mm to 040 mm and length to 400 mm. There are two types of rods available: polished and unpolished.To guarantee the quality of products, strength of every rod is tested. In addition, TRS (Tensile Rupture Strenght) measurement is done on randomly chosen unpolished details.

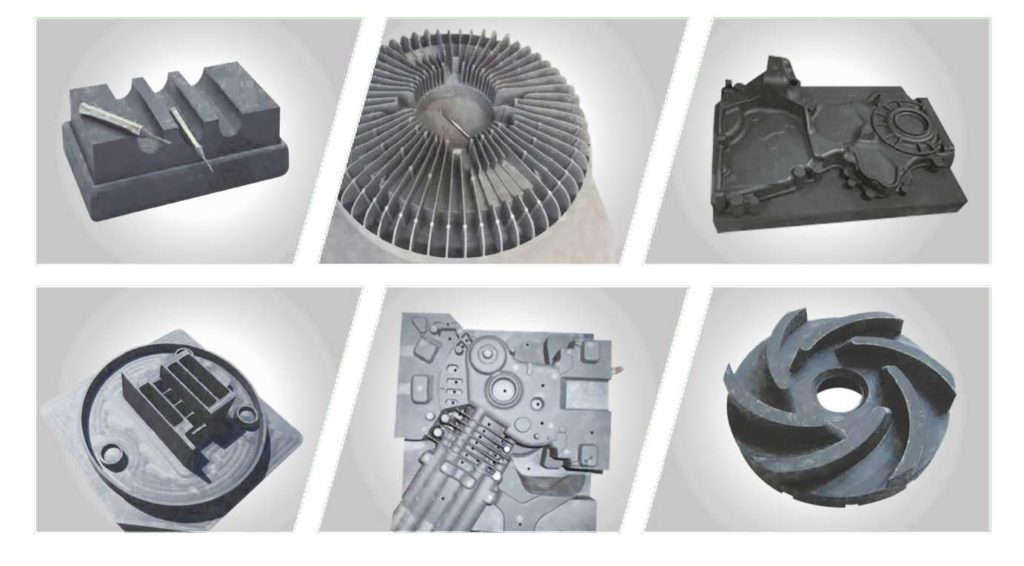

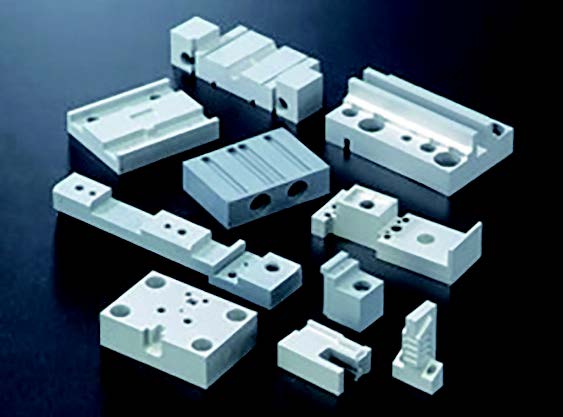

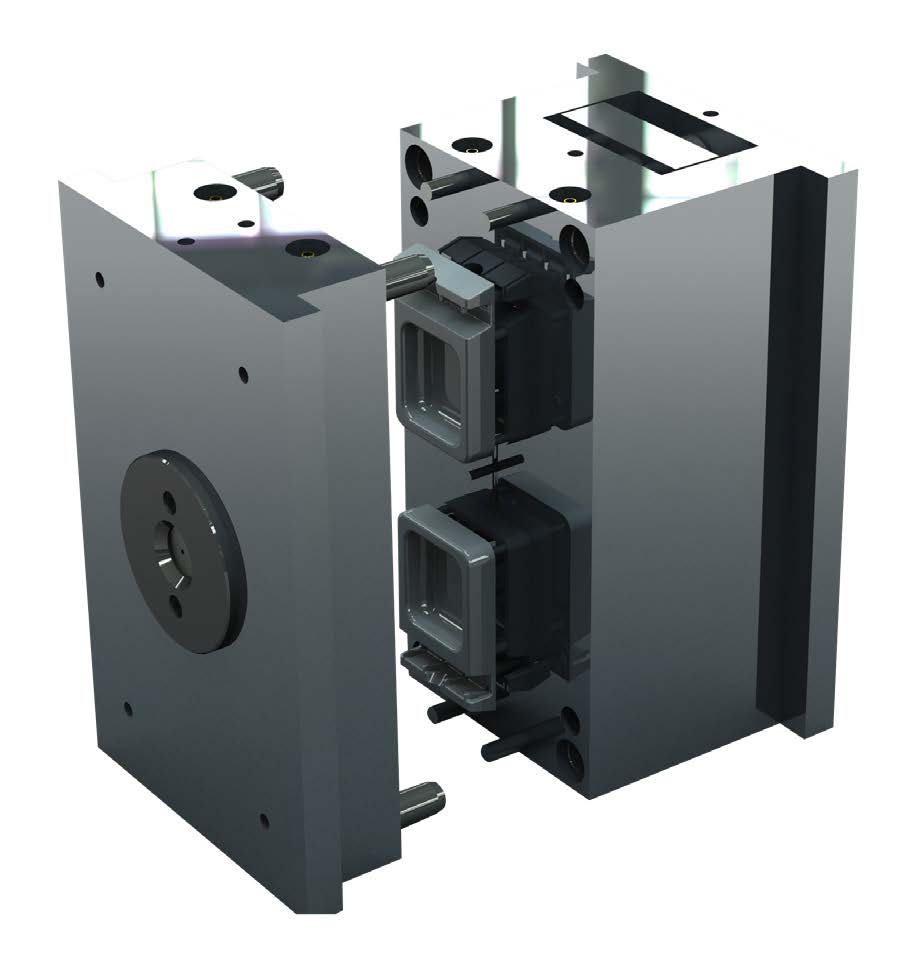

Carbide parts are used in a wide variety of fields including machine parts and industrial devices. Accessible semi-finished sinter parts allow toolmakers to fabricate carbide items at competitive prices. Super Carbides’ advanced machine park allows manufacturing products with a complex geometry with minimal surpluses for finishing machining. Depending on a complexity of a product, technology of a semi-finished product production is optimised.minimal surpluses for finishing machining. Depending on a complexity of a product, technology of a semi-finished product production is optimised.

Carbide grades table

TCU90

Co – 9.0%

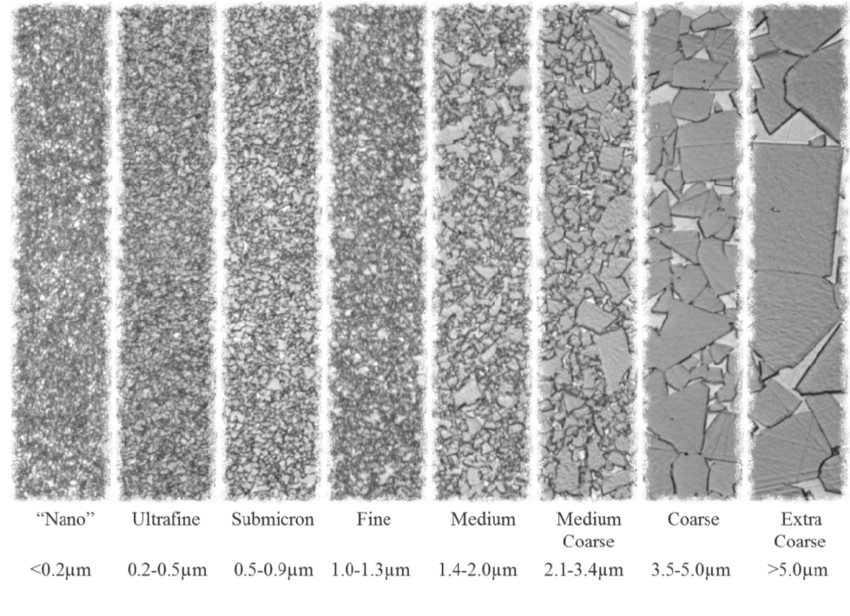

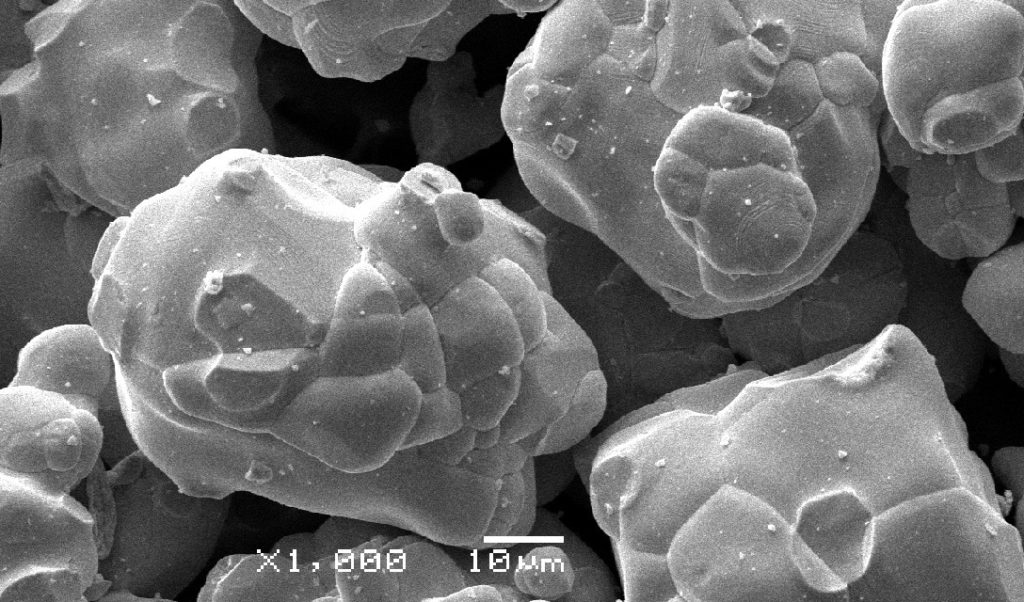

Grain size – 0.2 µm

Density – 14.35 g/cm3

Hardness – 94.1 HRA

TRS – 5200

Material for cutting tools machining quenched materials (HRC65 -70), hardwood and high polishing cutters. Finish machining 316L stainless steel.

TCF06

Co – 6.0%

Grain size – 0.6 µm

Density – 14.80 g/cm3

Hardness – 93.1 HRA

TRS – 4000

Material for machining Al-Mg alloy, non ferrus metal, glass fiber, carbon fiber, composite material, graphite, denture and ceramic.

TCS06

Co – 5.0%

Grain size – 0.9 µm

Density – 14.82 g/cm3

Hardness – 92.3 HRA

TRS – 3200

Material for machining graphite, silumin and carbon fiber composite material. Excellent coating adhesion.

TCU06

Co – 6.0%

Grain size – 0.4 µm

Density – 14.08 g/cm3

Hardness – 94.3 HRA

TRS – 4600

Material for PCB micro-drill and end mili machining super high hardness Material.

TCU08

Co – 8.0%

Grain size – 0.4 µm

Density – 14.52 g/cm3

Hardness – 93.5 HRA

TRS – 4800

Material for PCB micro-drili, mini miliing cutter.

TCF08S

Co – 8.0%

Grain size – 0.3 µm

Density – 14.50 g/cm3

Hardness – 93.6 HRA

TRS – 5000

Material for Micro PCB drill, cutting tools finish machining quenched material (HRC60-65), 3 16L stainless steel, high polishing metal sheet and silicon steel sheet of motor.

TCU40

Co – 10.0%

Grain size – 0.8 µm

Density – 14.40 g/cm3

Hardness – 91.7 HRA

TRS – 4600

Material for common drili bit, end mili and punching die.

TCU40F

Co – 10.0%

Grain size – 0.6 µm

Density – 14.45 g/cm3

Hardness – 92.3 HRA

TRS – 4600

Material for cutting tools machining common drili bit, end mili, titanium alioy, stainless steel and gray cast iron.

TCU40S

Co – 10.0%

Grain size – 0.5 µm

Density – 14.50 g/cm3

Hardness – 92.5 HRA

TRS – 4800

Material for cutting tools machining 316L stainless steel, best Material for common circular cutter.

TCU44

Co – 12.0%

Grain size – 0.4 µm

Density – 14.10 g/cm3

Hardness – 92.6 HRA

TRS – 4800

Material for cutting tools machining tita- niumalloy, heat resistant alioy, stainless steel, quenched steel(HRC55and above), gray cast iron.

TCU25

Co – 12.0%

Grain size – 0.6 µm

Density – 14.05 g/cm3

Hardness – 92.3 HRA

TRS – 4200

Material for cutt ing tools machining heat treated steel(Hardness HRC45 and above), cast iron, stan lesssteel.

TCU45

Co – 13.0%

Grain size – 0.3 µm

Density – 13.95 g/cm3

Hardness – 92.7 HRA

TRS – 4800

Material for cutting tools machining titanium, heat resistant alloy, stainless steel, quenched steel (HRC55 and above).

TCU34

Co – 10.0%

Grain size – 0.8 µm

Density – 14.40 g/cm3

Hardness – 91.5 HRA

TRS – 3600

Economy grade. Material for cutting tools machining, common drili bit, end mili, titanium alioy, stainless steel and gray cast iron.

TCU03

Co – 3.0%

Grain size – 0.3 µm

Density – 15.23 g/cm3

Hardness – 94.6 HRA

TRS – 2560

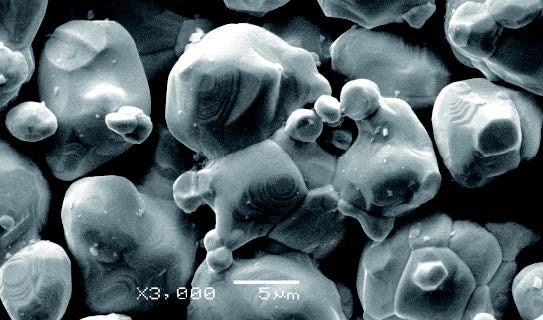

Nano grain size grade with super high hardness, toughess and cerrain corrosion resistance. Good general use character, can be applied to tools with large ratio of lenghr diametes

TCU05

Co – 6.0%

Grain size – 0.3 µm

Density – 15.01 g/cm3

Hardness – 94.3 HRA

TRS – 3200

Nano grain size grade, suitable for cutting high/medium density plate, polywood, soft wood, chipboard etc.

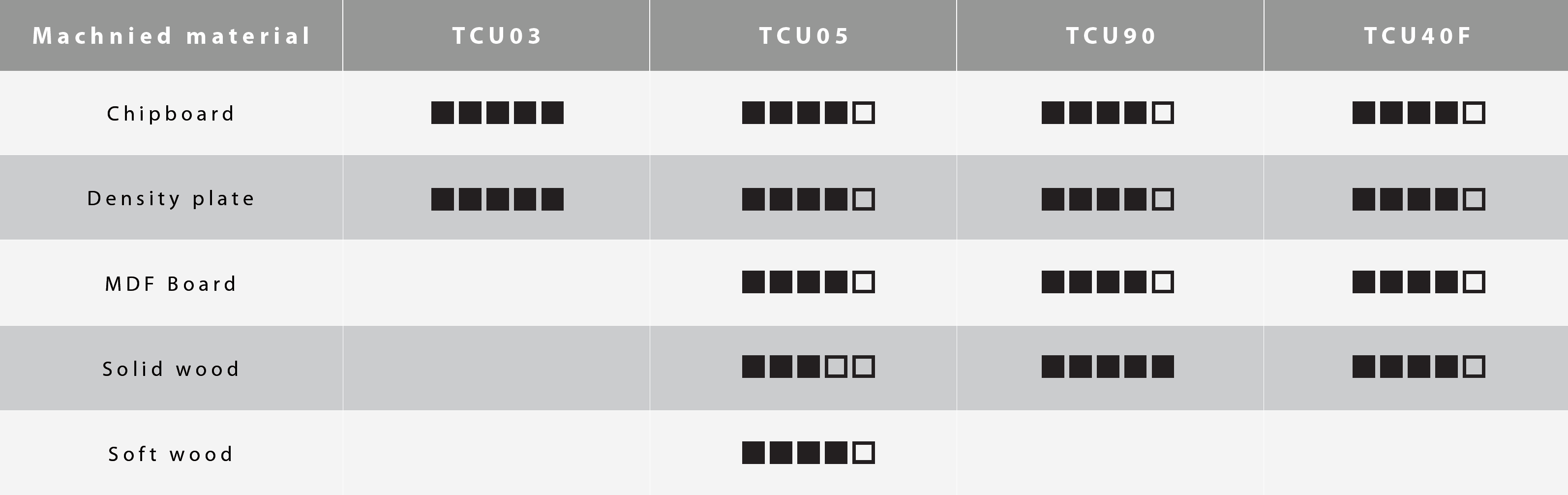

Wood processing recommendation table

High performance Grades

For High Hardened Steels - TCU90

Material for cutting tools machining :

• quenched materials (HRC65-70) ,

• hardwood and high polish ingcutters

• finish machining

• 316L stainless steel.

Nanograde – grain size: 0,2µm

High hardness and highest TRS 5200 coefficient

For Difficult to cut materials - TCU45

Material for cutting tools machining :

• Inconel and other heat resistant alloys,

• quenched steel (HRC55 and above)

• titanium alloy,

• stainless steel.

Our best material for HRSA materials.

For non-ferrous metals - TCU08S

Material for cutting tools machining :

• finish machining

• quenched material (HRC60-65),

• 316L stainless steel.

• high polishing metal sheet and silicon steel sheet of motor

General high strength grade - TCU44

Material for cutting tools machining :

• gray cast iron,

• titanium alloy,

• heat resistant alloy,

• stainless steel,

• quenched steel (HRC55 and above)

Our best material for grey cast iron.

Economy high strength grade - TCU40F

Material for cutting tools machining :

• gray cast iron,

• common drill bit and endmils,

• titanium alloys,

• stainless steel,

Our best material for grey cast iron.

High performance grades - TCF06 and TCS06

Material solution for CVD diamond coated tool:

• Graphite mould, electrode machining,

• Carbon fiber composite material machining,

• For machining difficult materials like silumin,

• For denture, ceramic machining,

Excellent coating adhesion.

TCF06 – For composite material. Al-Mg alloy, Graphite, denture and ceramic

TCS06 – For graphite, silumin and carbon fiber composite material.